inForm in Print: How We Built Our First-Ever Magazine

I’ve been in love with magazines for as long as I can remember, and it’s quite easy to trace my life through the magazines I have collected.

By the time I left home for university I had filled my childhood bedroom with countless boxes of old mags; Spin and Four Four Two from my sports-mad pre-teen years, Q and NME from when indie rock bands took over my affections, and Esquire and GQ from when everything came down to looking good on a Friday night. I now exclusively subscribe to Men’s Health and The New Yorker; make of that what you will.

As a consequence of this obsession, I had always wanted to put together and edit print magazines, a cavalier idea when “print is dead” forewarnings have become less a thing of the future, more a crushing ever-present.

It was with great surprise and joy then, when our CEO, Damian, set me the task of launching Form’s first-ever print magazine earlier this year. Damian is a great magazine lover too, but there was also the desire to offer our community something tangible, elevated from what we were offering through our inForm digital platform.

There are great health and mindfulness benefits in reading print over digital, from fewer distractions — be gone Wikipedia rabbit holes — to better retention of information, and less eye strain. A study conducted by Bournemouth University found that 60 percent of consumers say they do not do anything else at the same time when reading magazines compared to 35 percent for social media.

Finding writers was the easy bit — we’d already worked with a number of brilliant journalists through our digital offering. The main challenges would be design — which our brilliant designer Lucy took the lead on — and finding a printing company that would echo our environmental and sustainable principles.

That’s what took us to the corner of a business park cul-de-sac in the small town of Uckfield, 50 miles out of London, and Pureprint, a sustainable printing company that has been going in various forms since 1923. Many of the workers on the printing press floor have been with the company for decades, including Paul Bracey, the floor’s supervisor, who joined the company in 1982.

Back then the process was a great deal more arduous he told me as we visited the factory for the printing of inForm. Three workers would have to man one printer, running up and down the 20-foot long printing press making constant adjustments. These days the printer is looked after by just one person who is able to make adjustments from their control desk, saving a great deal of sweat in the process. Back in 1982, the printer would also only manage around 5,000 prints an hour. Now the printers can do 18,000.

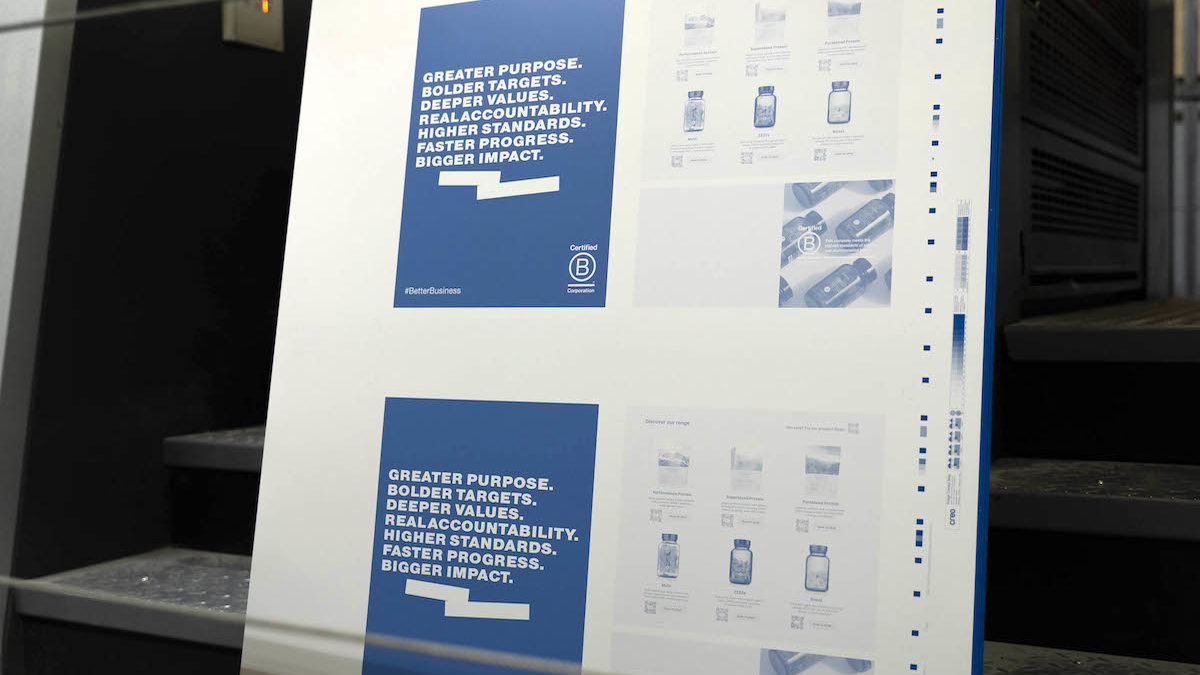

Both printers were lithographic though, a technique invented by German playwright Alois Senefelder in 1796 from which an inked image is transferred (Senefelder used a slab of limestone) onto a printing surface. Pureprint uses aluminium plates in their production, which when used are then given to a local car manufacturer for re-use.

While it takes longer to set up a lithographic printer than a digital printer, it’s quicker to do high quantities of high-quality repeat items, which makes it ideal for large print runs like our order of 10,000. Along with the recycling of the aluminium plates, we were also able to bring sustainability into the printing process through our choice of a recycled, Forest Stewardship Council certified paper.

By choosing this paper we were able to guarantee an audited chain of custody through to the finished magazine, while the paper was also carbon balanced with the World Land Trust, an international conservation charity that offset carbon emissions through the purchase and preservation of high conservation value land.

In protecting standing forests under threat of clearance, carbon is locked in that would otherwise be released. These protected forests are then able to continue absorbing carbon from the atmosphere, referred to as REDD (Reduced Emissions from Deforestation and forest Degradation), which is now recognised as one of the most cost-effective and swiftest ways to arrest the rise in atmospheric CO2 and global warming effects.

It’s funny to think that while print magazines are supposedly dying out, the actual process by which magazines are being printed has never been so sustainable, efficient, and of such high quality. Here at Form, we believe there will always be a place for beautiful, informative print journalism, and we hope you enjoy the magazine that we have put together for you.

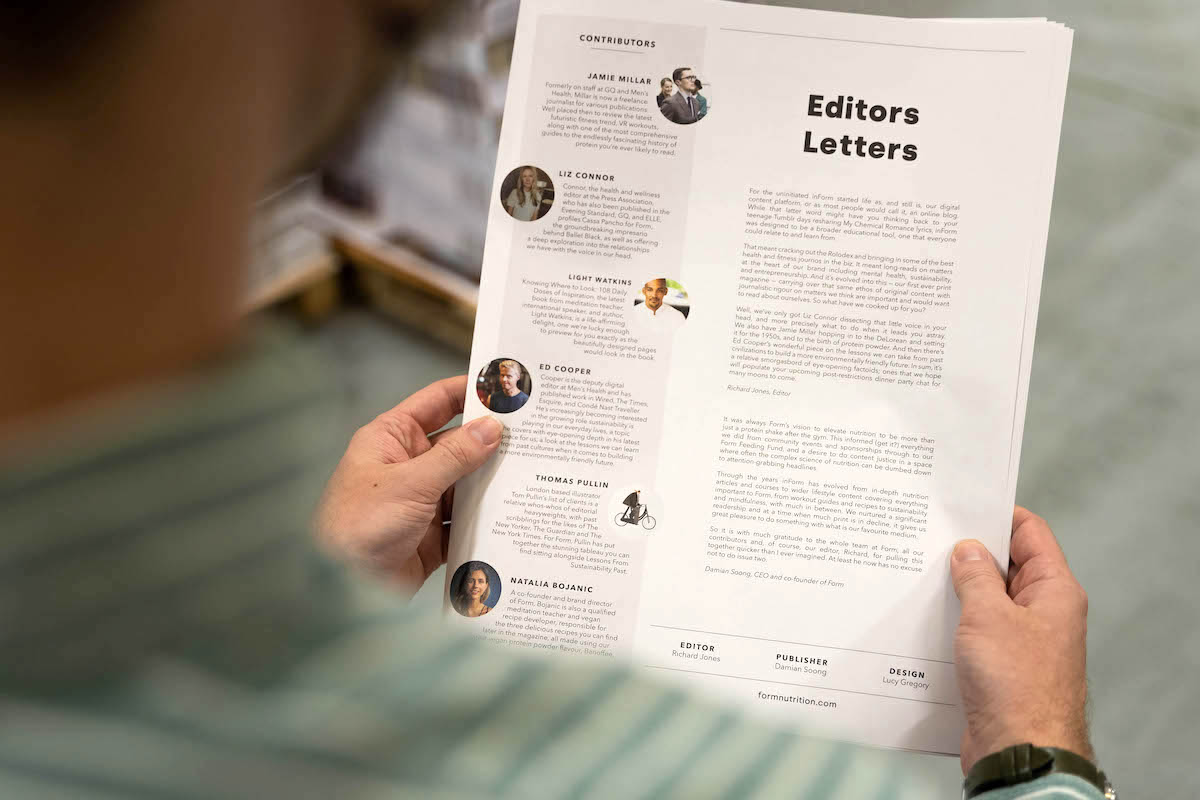

Inside you’ll find Liz Connor dissecting that little voice in your head, and more precisely what to do when it leads you astray. We also have Jamie Millar hoping into the DeLorean and setting it for the 1950s, and to the birth of protein powder. And then there’s Ed Cooper’s wonderful piece on the lessons we can take from past civilizations to build a more environmentally friendly future.

In sum, it’s a relative smorgasbord of eye-opening factoids; ones that we hope will populate your upcoming post-restrictions dinner party chat for many moons to come.

Find issue one of inForm in your product orders through August and September.